MakSpeed Technologies is a technology driven organization providing advanced products and services in the field of Flow Chemistry and Process Intensification.

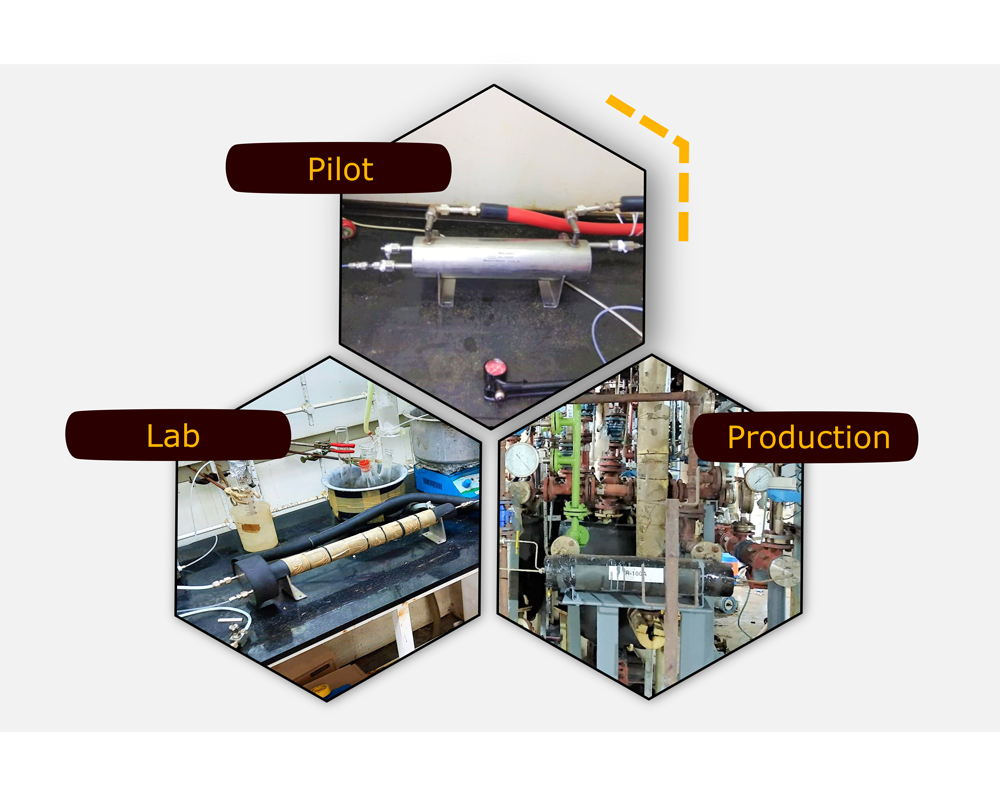

We help our customers in successful adaptation and implementation of Flow Chemistry Technology at laboratory, pilot, and production scale.

Our Flow Chemistry Products provide inherently safer and efficient alternative to produce chemicals in the Pharmaceutical, Agro chemicals, Fine and Specialty chemicals, Petrochemicals, Flavors and Fragrances (F&F), Dyes and Pigments industries. These can be used for development of new processes or converting existing batch process to continuous process. We offer standard product line as well as develop customized solutions for our customers as per specific requirements.

Along with the products, through our process development services, we support our customers throughout the Flow Chemistry implementation journey.

Through our training offerings, we also contribute to building skilled talent pool necessary for accelerated adaptation of technology in the industry.

We are committed to continuously innovate and develop advanced products that enable faster, cleaner and efficient chemical processes.